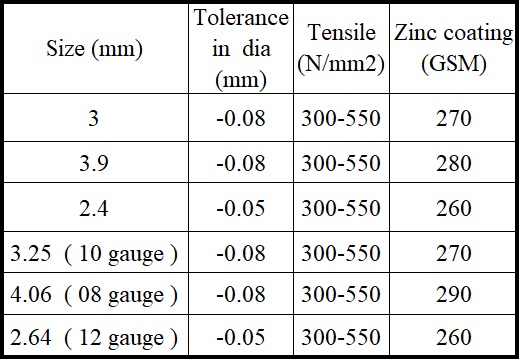

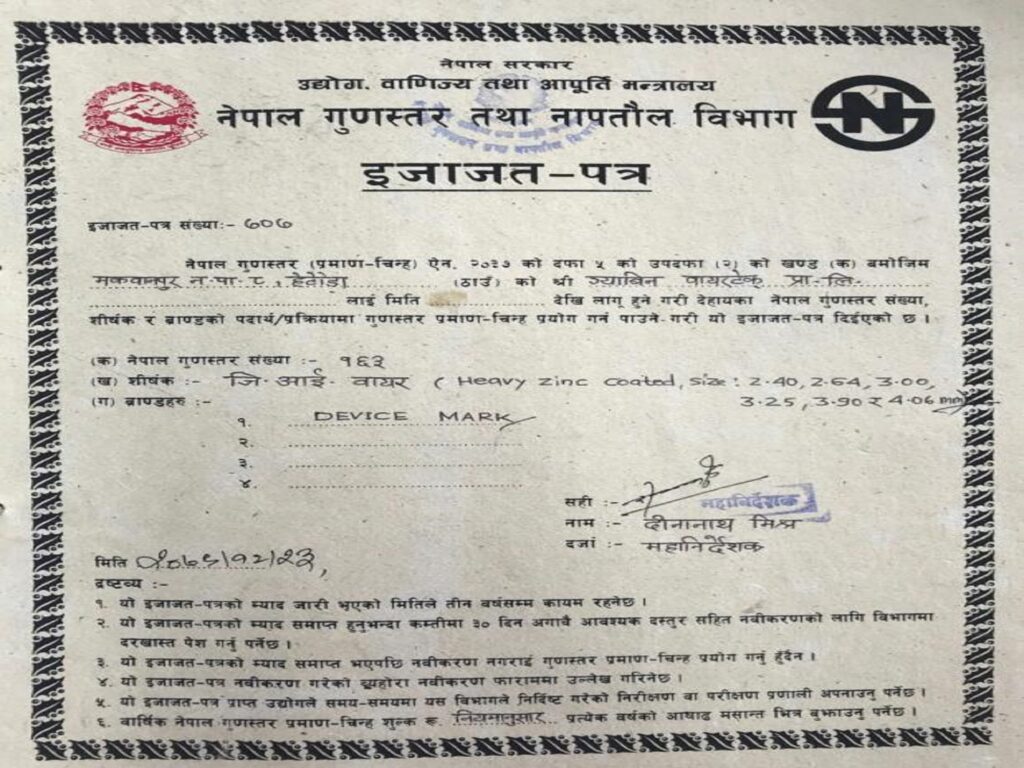

Quality Control Standardization as per NS 163.

Zinc coating – A fully functional chemical lab is set up to test each and every coil that is manufactured in the plant, as per NS 163.

Uniformity test – Zinc uniformity is attained by carrying out test on samples multiple times from the same coil, as per NS 163.

Tensile strength – A tensile tensing machine is set up in the physical lab to test the physical parameters of each and every wire rod or GI coils that are in the plant, as per NS 163.

Adhesion test -10 turns of the wire is done using torsion testing equipment set up in the plant. Every sample undergoes this test so that all the hardness, tensile and coating parameters are in tune with the desired standard quality, as per NS 163.

Sizes and Dia – We strictly adhere to Mitutoyo made measuring screw gauge and calipers in all of our process flow, as per NS 163.